One of the most common questions we’re asked at Wood and Beyond is “what is engineered wood flooring made of?”. In fact, engineered wood flooring is arguably one of the most misunderstood flooring products on the market today and we think this is a real shame. With some really significant advantages over solid wood, it’s a flooring solution that is well worthy of consideration, yet is often confused with the likes of laminate flooring, which for us is heartbreaking! In this article we want to help you get up close and personal with engineered wood flooring so you can start to love it in the same way as we do!

The basic structure of engineered wood flooring

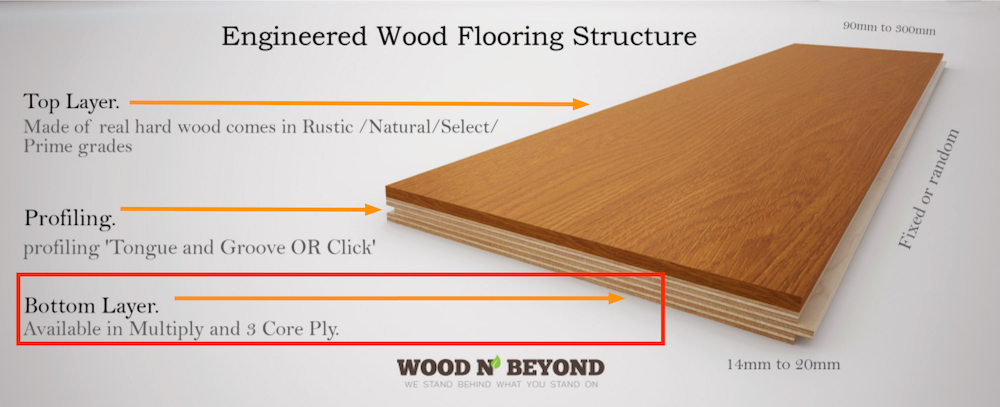

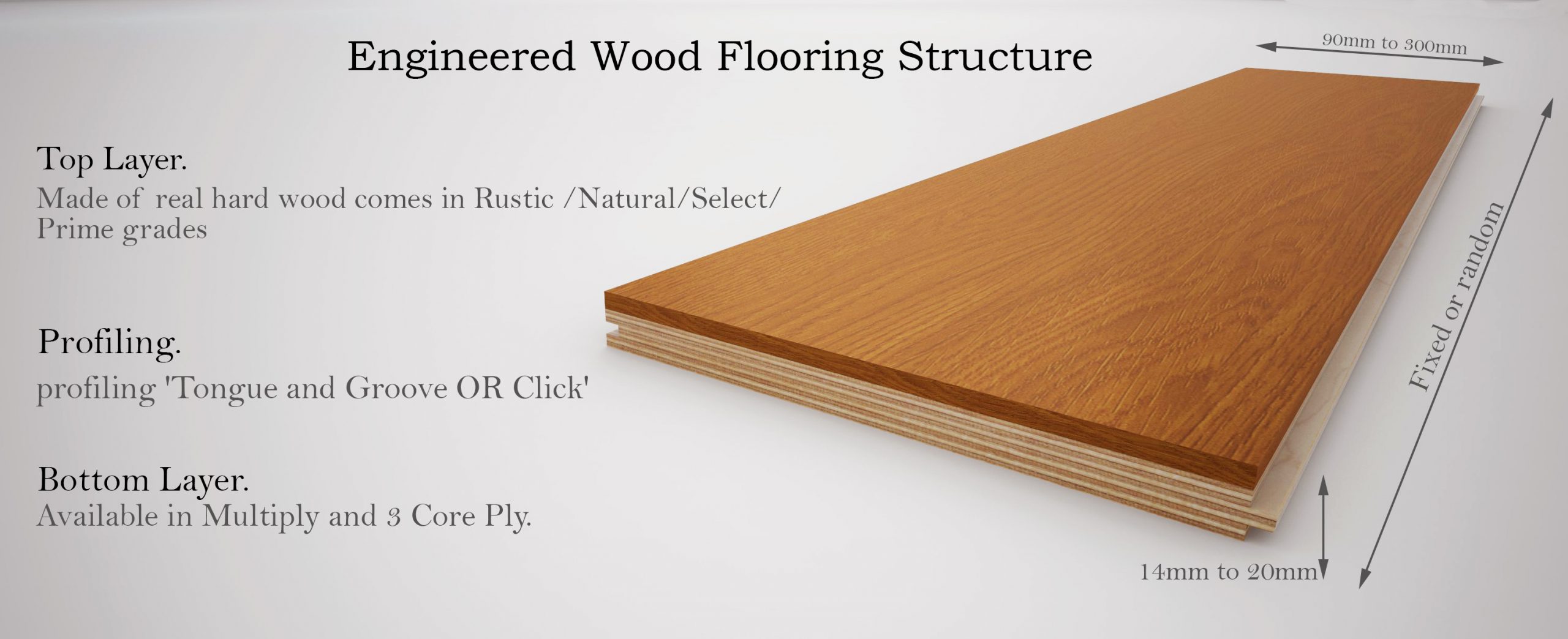

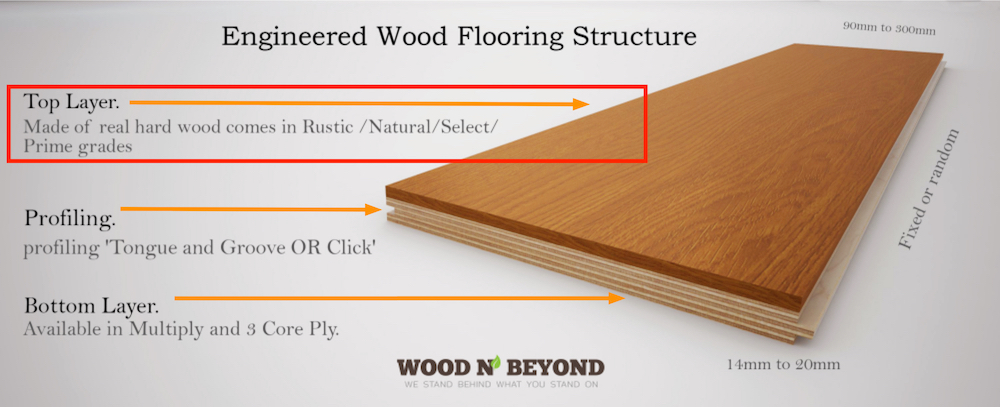

Engineered wood flooring is made up of anything between 3 and 12 layers of ply. These layers of ply are cross layered, then glued and pressed together to form a really strong bond. It’s this bonded core board that makes engineered wood flooring so very different from solid wood flooring.

Once the core board has been cut into flooring planks, the tongue and groove are created. In effect, the more layers of ply a board has, generally speaking the tougher it will be. For example, a 3 ply board will have a single core board, a base layer and a real wood top layer or lamella. The problem with many 3-ply engineered wood floor solutions is that the core board, where the tongue and groove fit together can become fragile, so generally speaking, if your budget allows, you should choose a multi-layer board.

How is it made?

As already mentioned, the core board of engineered wood flooring is made by bonding layers and layers of ply together. Thereafter, the top layer is added and it’s that layer that really makes the end result look so good. There are two different ways to obtain the top layer of solid wood for engineered wood flooring. The first is called slicing or sawing and the second is called rotary cutting.

A sliced veneer is made by cutting through cross sections of a tree trunk. A rotary cut veneer is made by effectively cutting a thin layer from all the way round the tree trunk to create a veneer ‘sheet’. Once the veneers have been cut from the tree, they are then bonded on to the top of the core board to give its finish and incredibly good looks. Not surprisingly, a sliced or sawn veneer can be cut thicker than a rotary cut veneer. Although a sliced or sawn veneer gives a more natural look to the wood, if it’s a more dramatic grain effect you’re looking for, you might be best to choose a rotary cut.

What makes it so special?

The thing that makes engineered wood flooring so special is the strength of its core board. As you can imagine, anything that is made up of a combination of various layers of ply that are bonded together using a strong adhesive will be stronger than a single piece of wood of the same thickness. This is important because it affects the stability of the floor.

Stability means the floor’s ability to remain consistent even when conditions change. Imagine a situation where temperature and moisture levels are fluctuating, a situation that’s particularly common in the likes of bathrooms and kitchens. In these conditions, solid wood expands and contracts significantly but engineered wood flooring is much less affected.

Why is this important? In effect, excessive expansion and contraction can play havoc with floors, creating unsightly and draughty gaps as well as significantly increasing the risk of cupping and, or bowing. Thanks to the way engineered wood flooring is made, the core board stays stable, in all but really extreme conditions.

What do the different thicknesses mean?

In the same way as solid wood flooring, engineered wood flooring is made in different thicknesses. That said, there are effectively two elements to the thickness of an engineered wood flooring board; the overall board thickness and the top layer or lamella thickness.

So, when you see a figure like 18/5 or 14/3, this means that the boards are 18mm and 14mm thick respectively with corresponding top layers of 5mm and 3mm. When you’re choosing the thickness of your board, you need to be careful to choose the best option for your project. Generally speaking, a board of more than 14mm thick isn’t recommended over under floor heating and a board of less than 18mm thick isn’t suitable for structural projects. All of that said, when it comes to precise technical details, you’re best to call on the advice of an expert every time.

What about species, grades and finishes?

No matter what species, grade or finish you want, you should be able to track it down in engineered wood flooring, the same way you can in solid. What this means is that engineered wood flooring is far from any sort of compromise – it really is win:win!

If you’d like to ask more questions about engineered wood flooring, we’re here for you. All you need to do is get in touch and one of our enthusiastic team will help!

—

FAQ

What is engineered wood flooring made of?

Engineered wood flooring is made up of 3 to 12 layers of cross-layered ply, glued and pressed together to form a strong bond, which forms the core board. This core board is then cut into flooring planks. A top layer or lamella, which is a layer of solid wood, is added on top of the core board. This solid wood layer can be obtained through slicing/sawing or rotary cutting from a tree trunk.

How is the strength of engineered wood flooring determined?

The strength of engineered wood flooring largely comes from the strength of its core board. This core board, made from various layers of ply bonded together using strong adhesive, is typically stronger than a single piece of wood of the same thickness. The more layers of ply a board has, the tougher it generally is.

Why is engineered wood flooring more stable than solid wood flooring?

Engineered wood flooring is more stable than solid wood because of its ability to remain consistent even when conditions such as temperature and moisture levels change. This stability helps prevent unsightly gaps, cupping, or bowing that can occur due to the expansion and contraction of solid wood in fluctuating conditions.

What do the different thicknesses in engineered wood flooring mean?

The thickness of an engineered wood flooring board is typically expressed in a figure like 18/5 or 14/3. The first number (18 or 14) represents the overall board thickness in millimeters, while the second number (5 or 3) indicates the thickness of the top layer or lamella, also in millimeters.

Can I get different species, grades, and finishes in engineered wood flooring?

Yes, engineered wood flooring is available in various species, grades, and finishes, just like solid wood flooring. This means you can choose the type of engineered wood flooring that suits your aesthetic and functional requirements.