BJELIN Hardened Oak Wood Flooring Click Mineral Grey UV Lacquer 11.3/0.6mm By 206mm By 2200mm

BJELIN Hardened Oak Wood Flooring Click Mineral Grey UV Lacquer 11.3/0.6mm By 206mm By 2200mm

This BJELIN Hardened Oak Wood Flooring is a stalwart display of quality and craftsmanship. Constructed in 11.3/0.6mm thickness, each plank measures a considerable 206mm by 2200mm. The boards are treated with a mineral grey UV lacquer, giving them a bespoke, stylish finish that is as durable as it is beautiful. The oak is hardened, offering a robust surface to withstand the wear and tear of daily life. The product grade is 'Select', an indication of its high standard.

Here is a clear summary of this flooring's core characteristics:

- Bespoke mineral grey UV lacquered finish

- Hardened oak wood construction

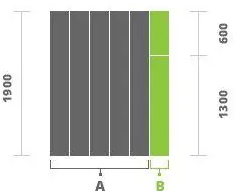

- Board dimensions: 11.3/0.6mm thickness by 206mm by 2200mm length

- Select grade of quality assurance

- Each board presents as a stylish plank style

When you usher in BJELIN Hardened Oak Wood Flooring into your home, you are embracing style and substance. The mineral grey UV lacquer finish is at once contemporary and timeless, versatile enough to suit a wide array of décor styles. Imagine stepping into a room furnished with this exclusive flooring: elegant, warm and inviting, it is the centrepiece that ties everything else together. Please note that the 'bespoke' description refers to the finish and colour only, encompassing the unique artisanal finish seen in each plank.

The new innovation from the Swedish company Valinge.

This product features patented Woodura® surface technology which is based on fusing a thin sheet of real wood veneer with a high density Compositek™ core through a powder mix layer. This creates a significantly stronger surface, 3 x harder than a traditional wooden floor.

The Woodura surface technology is also highly sustainable - it enables 10 times more flooring to be produced from the same amount of timber compared to traditional engineered wood flooring.

- UV acrylic top coat

- Natural wood covering

- Wood-based powder layer

- Välinge CompositekTM core

- Wood-based powder layer

- Natural Wood backing layer

Water-Resistant & Worry Free - The exceptionally high density makes the product highly water-resistant and the addition of the 5G® Dry™click system provides enhanced water-resistance by preventing water from penetrating into the joints.

When you've received your flooring, you should within one hour store it inside, completely flat and in sealed boxes until you are ready to lay it. Boxes should be kept inside your house (not in a garage or other outbuilding). During storage, please make sure that your flooring is well away from extreme heat (radiators) and moist areas (recently plastered walls, damp basements etc). We recommend an acclimatizing period of at least one week, during which time flooring needs to be kept in sealed boxes at room temperature. Engineered flooring need to stay in the boxes at the room temperature for 48 hours (for installation without underfloor heating) or 7 days (for installation with underfloor heating) and the room temperature must be at least 21-22 degrees Celsius for 7-14 days - the floor surface temperature must be a minimum of 21 degrees Celsius - the air relative humidity must be between 40% and 65%.

Free sample are available to order. The sample will allow you to feel the high quality of our wood and see its beautiful rich markings.

We aim to dispatch the sample within a day so you won't have to wait long.

Simply choose the 'Free Sample' option and complete the secure checkout process.

We strongly recommend to order a sample and not rely only on the photos on the web.

Due to the nature of the products, description and images should only be used for guidance.

It needs to be installed on top of 100% straight, rigid and even subfloor.

When installing on top of screed the screed moisture must not exceed 2%. Please make sure that the fitter will have the correct tools and knowledge on how to check the screed humidity.

New Screed: Need to apply 1 or 2 layers of DPM before installation.

You must create an expansion gap of 12-18mm for expansion gap.

Floating: When Floating Tongue and Groove system, the tongue and groove needs to be glue together.

We strongly recommend that Engineered flooring must be installed by a professional fitter with all the correct tools and knowledge.

We recommend treating your flooring with accordance to our maintenance guides every 3-12 weeks (depends on traffic and need) with the following:

Finish Type

Maintenance product

Frequency

UV Oiled

Every 2-3 weeks especially in areas with high traffic

UV Lacquered

Every 2-3 weeks especially in areas with high traffic

Wax Oiled

Apply 1-2 coats post-installation; additionally apply Ware Care every 2-3 weeks.

Please always try on an offcut or a small corner to see that you are happy with the result before applying on your floor.

It needs to be installed on top of 100% straight, rigid and even subfloor.

When installing on top of screed the screed moisture must not exceed 2%. Please make sure that the fitter will have the correct tools and knowledge on how to check the screed humidity.

New Screed: Need to apply 1 or 2 layers of DPM before installation.

You must create an expansion gap of 12-18mm for expansion gap.

Floating: When Floating Tongue and Groove system, the tongue and groove needs to be glue together.

We strongly recommend that Engineered flooring must be installed by a professional fitter with all the correct tools and knowledge.

The full product's information can be found on the following link:

[Valinge Flooring Downloads and Videos]